Products Center

PRODUCTS SHOW

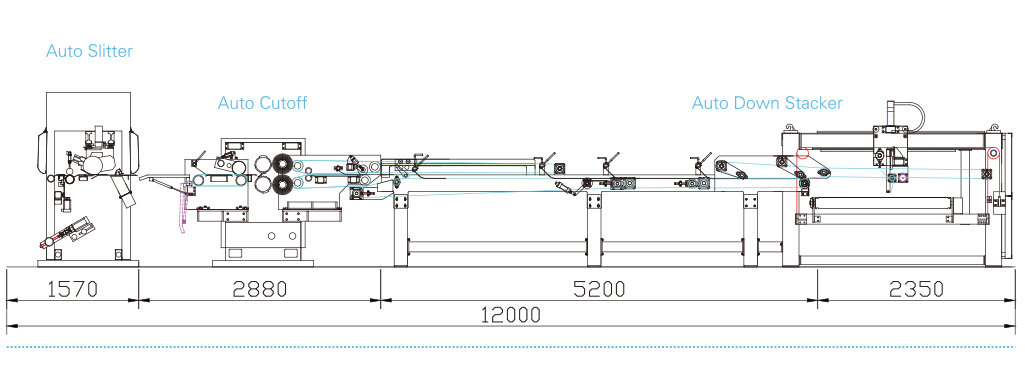

| No. | Equipment | Set | Description | |

| 1 | Automatic Thin-blade NC Slitter | 1 |

Servo controlled constant-tension synchronized conveying, Optional auto trim waste cutting, Optional auto paper alignment. |

|

| 2 | Automatic Spiral-knife NC Cutoff | 1 |

Servo controlled precision cutting, Servo controller paper feed-in & feed-out, Optional auto color-mark tracking cut. |

|

| 3 | Automatic Basket Down Stacker | 1 |

Servo controlled board shingle, Accurate board count, Auto change pile, change order, Neat stacking, Auto transverse expulsion, Rear-stopper auto adjust. |

|

| Effective width | 1800、2200、2500mm | Slitter positioning | ±0.5mm |

| Max. speed | 200m/min | Cutting length | 350~1700mm |

| Slitter config. | 5、6、7 | Cutting precision | ±1mm |

| Min. Slitter-spacing | 160mm | Stack height | 250mm |

| Order change time | 1s | Stack length | 1700mm |

|

NO. |

Model-Width-Speed-Slitter-Length-Height |

Dimensions L x W x H (mm) |

Weight (Ton) |

Power (KW) |

|

1 |

KTDW-QZD-1800-200-5-1700-250 |

10000x6700x2200 |

21 |

46 |

|

2 |

KTDW-QZD-2200-200-6-1700-250 |

10000x8100x2200 |

24 |

57 |

|

3 |

KTDW-QZD-2500-200-7-1700-250 |

10000x8400x2200 |

27 |

68 |

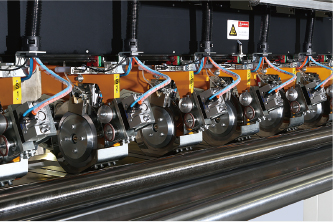

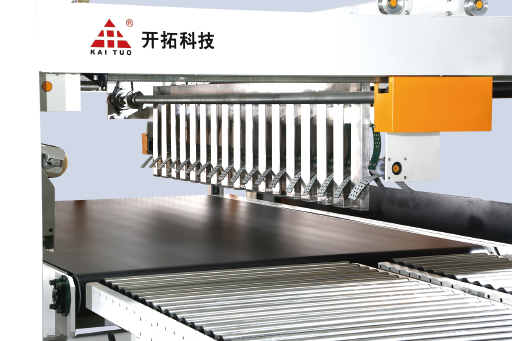

Automatic Thin-blade NC Slitter

◆ Servo controlled constant-tension conveying of board, conveying speed synchronized with Single-facer speed.

◆ Alloyed steel thin-blades, Auto sharpening & lubrication, long-lasting blades, high-quality slitting.

◆ Individual servo motor & controller on each Slitter sets, quick and accurate order change.

◆ Slitters are AC servo controlled, speed synchronizes with board speed.

◆ Standard trim suction-inlet, Auto positioning according to border blade.

◆ Individual sealed electrical cabinet, equipped with Industrial air-conditioner,Dust-free, constant temperature and humidity ensures longer life-span of electrical components.

◆ Standard 10″touch-screen monitor, easy to operate.

◆ Standard communication interface, easy to link with Management system.

◆ Optional auto trim waste cutting, auto cut the trim waste during order change.

◆ Optional auto paper alignment, auto track the paper edge & align the paper from deviation.

◆ Optional trim suction system, auto suction & shatter the trim waste and convey to the packaging machine.

◆ Designed and manufactured according to CE standards.

|

Servo controlled constant-tension synchronized conveying |

Alloyed steel thin-blades, Servo controlled positioning |

Auto positioning of Trim suction-inletaccording to border blade Auto cut trim, auto suction |

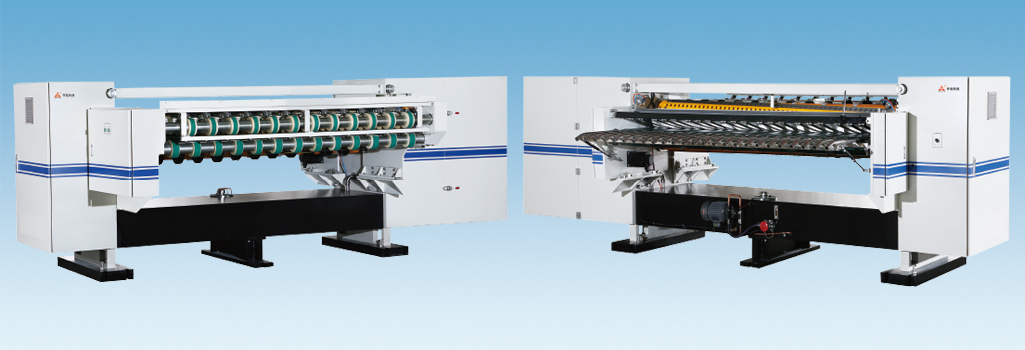

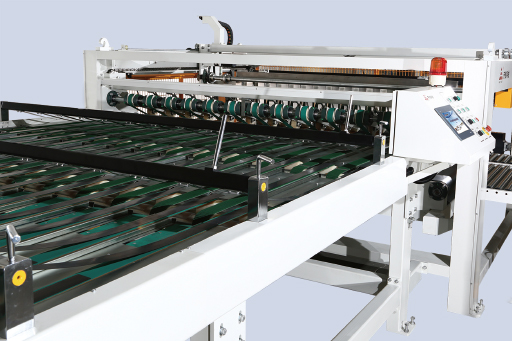

Automatic Spiral-knife NC Cutoff

◆ Frame-structure, Module-design, precision machining, precision assembly ensures long-term stable performance.

◆ Alloyed steel seamless tube, spiral-knife shaft with precision needle bearings, precision machining, dynamic balancing, ensures high rigidity, low inertia.

◆ Alloyed steel precision spiral-gear, Alloyed steel saw-teeth spiral-knife cutoff, ensures stable, neat, accurate cut.

◆ Permanent magnet synchronous AC servo motor compatible with AC servo controller, ensures high efficiency, accurate cut.

◆ AC servo motor & controller ensures stable & smooth feed-in & feed-out conveying.

◆ Twin clapping belts applied at feed-out side, servo controlled adjustment for the clearance between uppper& lower belts.

◆ Auto order change, auto order insert, auto cut order change waste.

◆ Standard spray lubrication system, ensures effective lubrication & heat radiation on gears & bearings.

◆ Standard energy storage capacitors, reactance, ensures stable operation and power saving.

◆ Designed and manufactured according to CE standards.

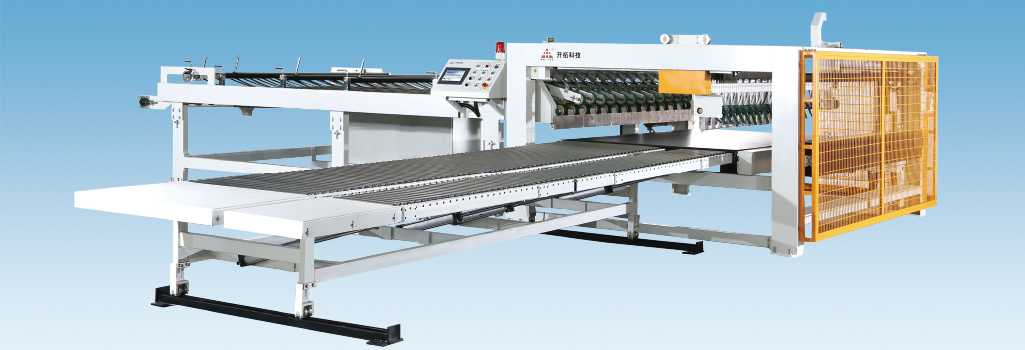

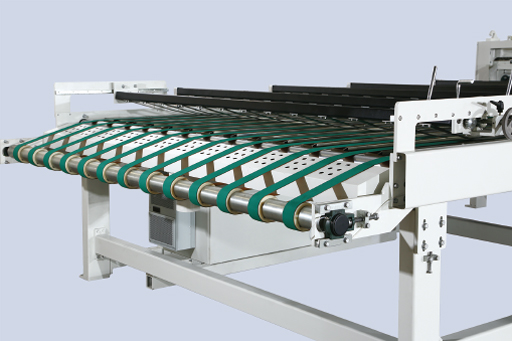

Automatic Basket Down Stacker

◆Four conveyor belt sections, Down-stacking, Accurate board count, Auto pile change/order change, neat stacking.

◆Vacuum system on the first belt section, controls neat shingle and stable convey of boards.

◆Boards smooth shingle on second belt section, convey speed auto adjusts during order/ pile change.

◆Twin clapping conveying belts on third belt section, the upper belt auto lifting.

◆AC servo motor & controller controls stable conveying, synchronizes conveying speed with production line speed.

◆Accurate counting, auto, quick & accurate pile/ order change.

◆AC servo controlled Auto flappers tidies and prevents curl on each board.

◆AC servo controlled Rear stopper, quick and accurate positioning during order change.

◆AC servo controlled smooth transverse expulsion when reaches stack height.

◆Standard foldable aluminum alloyed rollers, smooth on board surface, easy flip & re-pile.

◆Individual sealed electrical cabinet, equipped with Industrial air-conditioner,Dust-free, constant temperature and humidity ensures longer life-span of electrical components.

◆Standard 10” touch-screen monitor, easy to operate.

◆Standard communication interface, easy to link with Management system.

◆Designed and manufactured according to CE standards.

Component list

AUTOMATIC THIN-BLADE NC SLITTER

|

Mechanical Parts |

Brands/ Specifications |

|

Beam, base frame: High-strengthened rail steel |

Alloyed steel |

|

Thin-blade: Tungsten steel |

Alloyed steel |

|

Slitter main transmission: Precision spline shaft & hub |

Alloyed steel |

|

Slitter positioning: Precision rack & pinion |

Alloyed steel |

|

Slitter positioning: Precision linear guide & runner block |

SBC (Korea) |

|

High-strengthened timing belt |

GATES (America) |

|

High-strengthened conveyor belt |

HONGSBELT (Germany) |

|

Main transmission bearings |

NSK (Japan) |

|

Pneumatic cylinder, electromagnetic valve, pressure valve, etc |

MINDMAN (Taiwan) |

|

Electrical Control System |

Brands/ Specifications |

|

Slitter positioning: AC servo motor |

KINCO (Germany) |

|

Slitter positioning: AC servo controller |

KINCO (Germany) |

|

Auto alignment: AC servo motor |

KINCO (Germany) |

|

Auto alignment: AC servo controller |

KINCO (Germany) |

|

Slitter: AC servo motor |

Realland (China) |

|

Slitter: AC servo controller |

Schneider (France) |

|

Trim suction-inlet positioning: AC servo motor |

KINCO (Germany) |

|

Trim suction-inlet positioning: AC servo controller |

KINCO (Germany) |

|

Conveyor belt: AC servo motor |

KINCO (Germany) |

|

Conveyor belt: AC servo controller |

KINCO (Germany) |

|

Operator console: Color touch-screen |

Schneider (France) |

|

PLC |

Schneider (France) |

|

Detection control: Proximity switch, encoders, etc |

SICK (Germany) |

|

Low voltage apparatus: AC contactors, air switch, switch button, etc |

Schneider (France) |

AUTOMATIC SPIRAL-KNIFE NC CUTOFF

|

Mechanical Parts |

Brands/ Specifications |

|

Body & base: Frame-structure, module-design |

Alloyed steel |

|

Spiral-knife shaft & spiral-gears: Precision machining, dynamic balancing |

Alloyed steel |

|

Saw-teeth spiral-knife |

Alloyed stee(Taiwan) |

|

Main transmission bearings |

NSK (Japan) |

|

Electrical Control System |

Brands/ Specifications |

|

Cutoff: Permanent magnet synchronous AC servo motor |

Phase (Italy) |

|

Cutoff: AC servo controller |

Baumueller (Germany) |

|

Energy storage capacitor |

EPCOS (Germany) |

|

PLC |

Schneider (France) |

|

Detection control: Proximity switch, encoders, etc |

SICK (Germany) |

|

Low voltage apparatus: AC contactors, air switch, switch button, etc |

Schneider (France) |

AUTOMATIC BASKET DOWN STACKER

|

Mechanical Parts |

Brands/ Specifications |

|

Beams & pillars: Sand-blasting, powder-coating surface treatment |

High-quality I-steel, U-steel |

|

Conveyor rollers: Precision machining, dynamic balancing, hard chrome plating |

High-quality seamless steel tube |

|

High-strengthened timing belt |

GATES (America) |

|

High-strengthened conveyor belt |

HONGSBELT (Germany) |

|

Pneumatic cylinder, electromagnetic valve, pressure valve, etc |

MINDMAN (Taiwan) |

|

Electrical Control System |

Brands/ Specifications |

|

Conveyor belt: AC servo motor |

KINCO (Germany) |

|

Conveyor belt: AC servo controller |

KINCO (Germany) |

|

Twin conveyor belts gap adjust: AC servo motor |

KINCO (Germany) |

|

Twin conveyor belts gap adjust: AC servo controller |

KINCO (Germany) |

|

Down-stacking platform: AC servo motor |

Realland (China) |

|

Down-stacking platform: AC servo controller |

Schneider (France) |

|

Rear-stopper positioning: AC servo motor |

KINCO (Germany) |

|

Rear-stopper positioning: AC servo controller |

KINCO (Germany) |

|

Auto flappers: AC servo motor |

KINCO (Germany) |

|

Auto flappers: AC servo controller |

KINCO (Germany) |

|

Transverse expulsion: AC servo motor |

KINCO (Germany) |

|

Transverse expulsion: AC servo controller |

KINCO (Germany) |

|

Operator console: Color touch-screen |

Schneider (France) |

|

PLC |

Schneider (France) |

|

Detection control: Proximity switch, photoelectric switch, encoders, etc |

SICK (Germany) |

|

Low voltage apparatus: AC contactors, air switch, switch button, etc |

Schneider (France) |

Related Products

Join Us Now!

To get the latest news of the products and market

Contact Us

Tel : 0086-532-8897 7898

Fax : 0086-532-8897 7899

Add

Headquarter : Room1707, Plage Mansion Bld. 2, Shenzhen Road No.230, Laoshan District, 266101 Qingdao China

Production base : Lingang Industrial Park, Qingdao China

Contact Us

Tel : 0086-532-8897 7284

Fax : 0086-532-8897 7899

Add

Headquarter : Room1707, Plage Mansion Bld. 2, Shenzhen Road No.230, Laoshan District, 266101 Qingdao China

Production base : Lingang Industrial Park, Qingdao China

代码

代码

Copyright © 2020 Qingdao Kaituo-NC Equipment Co., Ltd. 鲁ICP备2021022831号-1 Powered by www.300.cn